Key Takeaways:

- An Industrial Single Board Computer (SBC) is a complete computer system designed for complex industrial systems.

- Industrial SBC are built to withstand harsh operating conditions and are used in manufacturing, transportation, energy, and automation industries.

- Industrial SBC have multiple expansion slots, support different operating systems, and offer advanced networking capabilities.

- They are used for machine control, process automation, fleet management, power generation, building automation, and more.

- Industrial SBC provide high reliability, compact form factor, and excellent performance compared to conventional solutions.

What is an Industrial SBC?

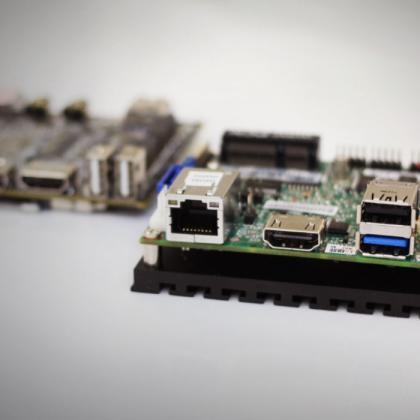

An Industrial Single Board Computer (SBC) is a complete computer system built on a single circuit board. It contains a microprocessor, memory, storage, and various input/output interfaces. Unlike consumer-grade SBCs, Industrial SBC are specifically designed to meet the demands of complex systems in industrial environments.

Definition and Features

Industrial SBC are designed to withstand harsh operating conditions such as extreme temperatures, high humidity, and excessive vibrations. They are built with high-quality components and undergo rigorous testing to ensure reliability and durability. These SBCs are commonly used in industries such as manufacturing, transportation, energy, and automation, where robust and stable computing systems are essential.

Industrial SBC offer a wide range of features that make them suitable for complex systems. They have multiple expansion slots and interfaces to connect with various industrial devices and peripherals. They also support different operating systems and programming languages, providing flexibility for software development and integration. Additionally, Industrial SBC often come with advanced networking capabilities, allowing seamless connectivity within a networked environment.

Applications in Complex Systems

Industrial SBC find extensive use in a wide range of complex systems across industries. In manufacturing, these SBCs are used for machine control, process automation, and data acquisition. They can interface with sensors, actuators, and other industrial devices to monitor and control production processes in real-time. Industrial SBC are also employed in transportation systems for fleet management, vehicle tracking, and passenger information systems.

In the energy sector, Industrial SBC play a crucial role in power generation, distribution, and management. They are used in control systems for power plants, substations, and renewable energy installations. Industrial SBC are also utilized in building automation systems for monitoring and controlling HVAC (Heating, Ventilation, and Air Conditioning), lighting, and security systems. These SBCs enable centralized management, energy efficiency, and predictive maintenance in complex building infrastructure.

Benefits over Conventional Solutions

Industrial SBC offer several advantages over conventional computing solutions in complex systems. One of the main benefits is their high reliability and longevity. These SBCs are designed to operate 24/7 in challenging environments without failure. They are built with components rated for industrial use, ensuring long-term operation without the need for frequent replacements.

Another advantage of Industrial SBC is their compact form factor, which allows for space-saving installations in tight environments. They can be mounted on DIN rails, in equipment racks, or directly integrated into machines and devices. This flexibility of installation makes them suitable for various industrial applications.

Industrial SBC are also known for their excellent performance and processing power. They are equipped with high-speed processors, abundant memory, and fast storage options. This allows for efficient data processing, complex computations, and multitasking in real-time applications. The increased processing power of Industrial SBC enables faster response times, higher productivity, and improved system performance.

FAQ

Question: What is the difference between an Industrial SBC and a consumer-grade SBC? – An Industrial Single Board Computer (SBC) is specifically designed to meet the demands of complex systems in industrial environments. It is built to withstand harsh operating conditions, undergoes rigorous testing for reliability and durability, and offers advanced networking capabilities, making it suitable for industrial applications.

Question: What are some key features of Industrial SBC? – Industrial SBC have multiple expansion slots and interfaces to connect with various industrial devices and peripherals. They support different operating systems and programming languages, providing flexibility for software development and integration. Additionally, they often come with advanced networking capabilities, allowing seamless connectivity within a networked environment.

Question: In what industries are Industrial SBC commonly used? – Industrial SBC are commonly used in industries such as manufacturing, transportation, energy, and automation. They find applications in machine control, process automation, fleet management, power generation, building automation, and more.

Question: What are the applications of Industrial SBC in complex systems? – Industrial SBC are used in manufacturing for machine control, process automation, and data acquisition. In transportation systems, they are employed for fleet management, vehicle tracking, and passenger information systems. In the energy sector, they play a crucial role in power generation, distribution, and management. They are also utilized in building automation systems for monitoring and controlling HVAC, lighting, and security systems.

Question: What advantages do Industrial SBC have over conventional computing solutions? – Industrial SBC offer high reliability and longevity, as they are designed to operate 24/7 in challenging environments without failure. They also have a compact form factor, allowing for space-saving installations in tight environments. Furthermore, Industrial SBC provide excellent performance and processing power, enabling efficient data processing, complex computations, and multitasking in real-time applications.

Question: Can Industrial SBC be customized to meet specific requirements? – Yes, Industrial SBC can be customized to meet specific requirements. They can be configured with the necessary expansion slots, interfaces, and other components to fulfill the needs of the target application or system.

Question: How do Industrial SBC ensure reliability in harsh operating conditions? – Industrial SBC are built with high-quality components and undergo rigorous testing to ensure reliability and durability. They are designed to withstand extreme temperatures, high humidity, excessive vibrations, and other challenging conditions commonly found in industrial environments.

Question: Can Industrial SBC communicate with other industrial devices? – Yes, Industrial SBC have multiple interfaces and networking capabilities that allow them to communicate with various industrial devices. They can interface with sensors, actuators, and other equipment to enable data acquisition, control, and integration within complex systems.

Useful Resources: